Leave the expensive manual labor of chocolate making to a smart machine

Increase production while maintaining high quality standards. Staff turnover and training is no longer a problem.

-

Load the chocolate into the tank of the machine and wait for it to become liquid. You can also load already melted chocolate into the tank, this will only speed up the work.

-

Set the chocolate’s working temperature and press the «pre-crystallization» button to start tempering the chocolate. This process takes up to 15 minutes.Set the chocolate’s working temperature and press the «pre-crystallization» button to start tempering the chocolate. This process takes up to 15 minutes.

-

Start working with an ATM: pour bars, make candies. Perfectly tempered chocolate pours out of the spout like tap water. 100 years ago a chocolatier could only dream of it! And if you connect an enrobing machine to an ATM, you can start the process of glazing the sweets automatically. There are many use cases. And this is the main advantage of the automatic tempering machine.

To start the chocolate bars manufacturing from dark, milk or white chocolate everything is ready right out of the box, no need to buy additional gadgets. The ATM comes with a vibrating table, designed for even distribution of chocolate in the mold and the removal of air bubbles out from the mass.

Sold separately.

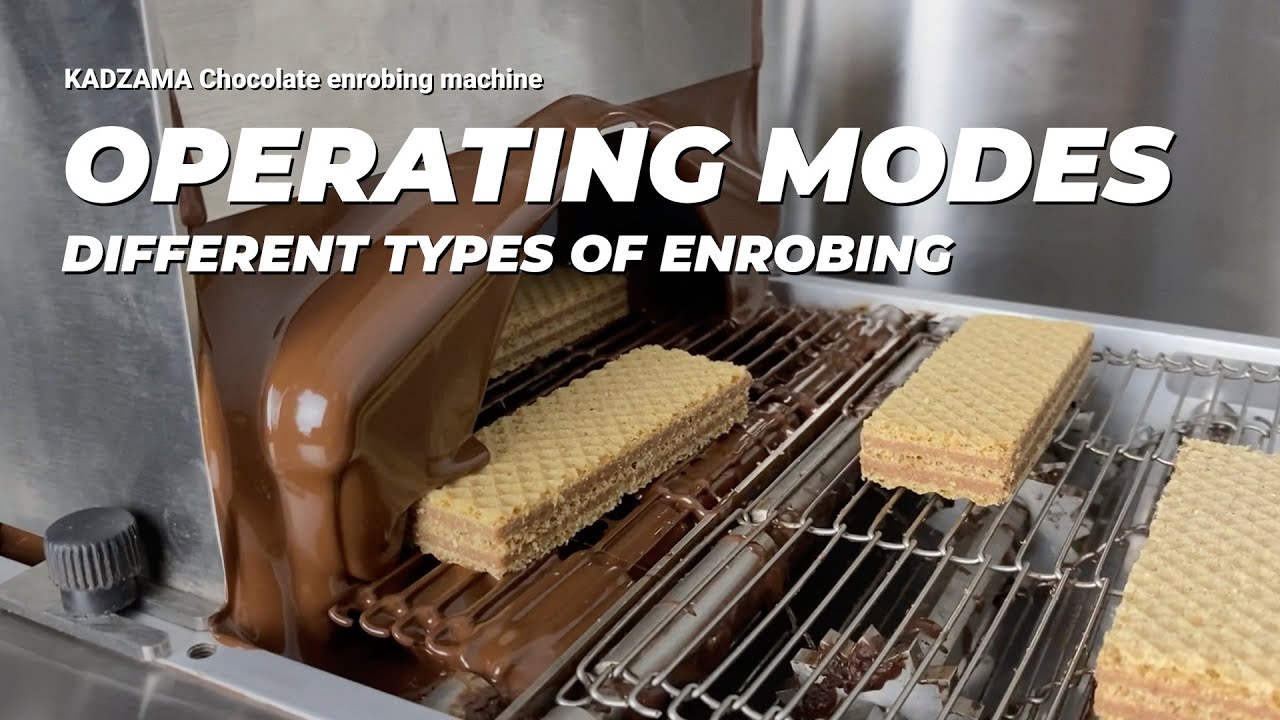

An ATM paired with a chocolate enrobing machine could take away manual glazing. No more dipping, tapping, backache and chocolate overrun. The result is always the same and most importantly, it’s easy to repeat.

Sold separately.

Dispensing plate is installed on the ATM drain spout and allows to make stuffed candies faster due to the precise delivery of the required amount of chocolate strictly to the cells.

Sold separately.

Additional caps for enrobing machine allow to cover a specific part of the product with chocolate: only the bottom or only half of the product. This opens up new possibilities for expanding the product range.

Always at your disposal.

| Dimensional size | 800 х 865 х 1440 mm |

| Weight | 175 kg |

| Loading capacity | 20 kg |

| Supply | 380 V (220 V — on demand) ~ 50 Hz |

| Power | 3,5 kW/h |

| Dimensional size | 838 х 960 х 1474 mm |

| Weight | 185 kg |

| Productive capacity | 90 kg / hour |

| Loading capacity | 30 kg |

| Supply | 380 V (220 V — on demand) ~ 50 Hz |

| Power | 3,7 kW/h |

| Dimensional size | 938 х 1000 х 1549 mm |

| Weight | 231 kg |

| Loading capacity | 60 kg |

| Supply | 400 V ~ 50 Hz |

| Power | 4,2 kW/h |

| Dimensional size | 1718 х 536,5 х 1185 mm |

| Weight | 68 kg |

| Supply | 220-240 V~50 Hz |

| Power | 0,6 kW/h |

| Dimensional size | 1718 х 636,5 х 1185 мм |

| Weight | 72 kg |

| Supply | 220-240 V~50 Hz |

| Power | 0,6 kW/h |

| Dimensional size | 300 х 170 х 120 mm |

| Weight | 5 kg |

| Material | Nozzles: AISI 304 stainless steel |

| Housing material | Aluminum |

| Length | 500 m |

| Thickness | 85-95 microns |

| Coverage | One - sided |

| Length | 500 m |

| Thickness | 85-95 microns |

| Coverage | One - sided |

We can offer not only the equipment, but also advise you on all the issues of manufacturing the chocolate and nut spreads. We will help you to choose the right equipment for your goals and share the best suppliers of quality ingredients.

Use sales@kadzama.com for all the inquiries or text us on WhatsApp

Sending...

Sending...