Coating machine 2 kg

Our website is not an online-store. It's online-catalog. Manager will contact you to clarify a cost of delivery and payment methods after you place your order.

The minimum order amount is 200 €

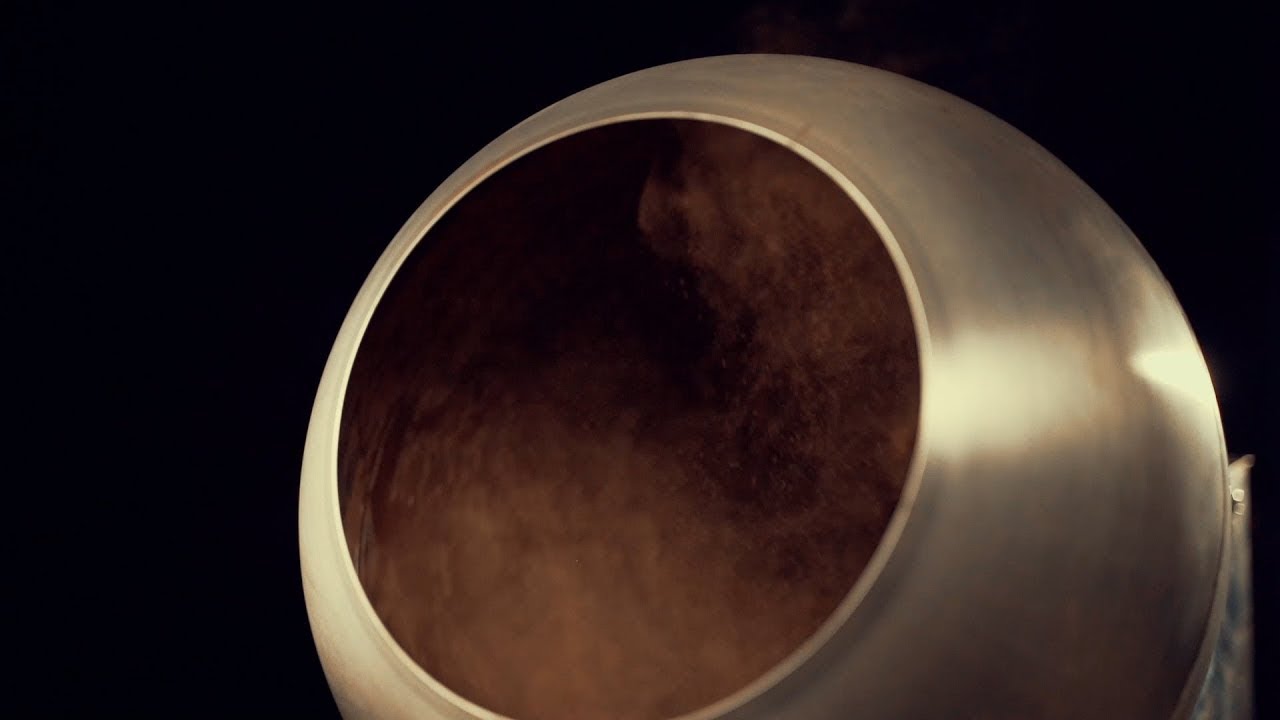

Small Coating machine (Panning machine) can produce dragee by evenly coating and mixing the product in the rotating drum.

It has two optimum speeds and convenient for different ingredients. Desktop version of the coating machine suits for home use, café, laboratory and for a small-scale production.

Complete set:- Housing – 1 pc.

- Bowl – 1 pc.

- User’s Manual – 1 pc.

- Warranty certificate – 1 pc.

| Dimensional size | 430х280х370 mm |

| Weight | 9 kg |

| Loading capacity | 2 liters |

| Supply | 220-240 V~50 Hz |

| Power supply system | Single-phase |

| Power | 0,1 kW/h |

| Housing material | Stainless steel AISI 304 |

| Bowl material | Stainless steel AISI 304 |

| Rotation speed | 30; 45 rpm |

| Number of speeds | 2 |

| Speed adjustment | Yes |

| Package overall size | 580 х 340 х 300 mm |

| Package weight | 10 kg |

| Warranty period | 2 year |

| Bowl size (diameter, height) | 280 x 240 mm |

Приобрели дражировочный барабан 2 года назад. В работе себя показал отлично.

Уже опробовала в работе. Отличный аппарат. Буду радовать своих клиентов вкусными орехами в шоколаде. В ближайшее время планирую еще заказывать оборудование Кадзама.

Yes, everything is fine. (220v / 60Hz)

Omar Fernando Ordoñez Rivera

I’ve tried the machine and it works well.

Thanks again and good job !

We had issues with motor but the company has arranged the spare part and after we changed the motor, it has been running smoothly, no issues ;-)

Bjarne

Поработаем????? Мой верный друг от @for_choco_biz

-

There may be several reasons.

Insufficient rotation time in the drum (the gloss did not have enough time to dry).

Solution: Increase the drying time (there is no exact time, a lot depends on the temperature/humidity in the room and the composition of the gloss). Dragees should not be sticky to the touch.

-

Humidity level in the room is too high (above 70%).

Solution: Reduce indoor humidity. For example, ventilate or turn the air conditioner on.

-

Incorrectly selected gloss.

Solution: Choose a gum arabic-based gloss.

-

The reason is the violation of the temperature regime during panning and / or storage of ready-made dragee. The optimal room temperature for dragee making is 18–20ºC. If the temperature is higher, surface defects may occur after panning.

Sending...

Sending...