Melangeur 20 kg (retro-styled)

Our website is not an online-store. It's online-catalog. Manager will contact you to clarify a cost of delivery and payment methods after you place your order.

The minimum order amount is 200 €

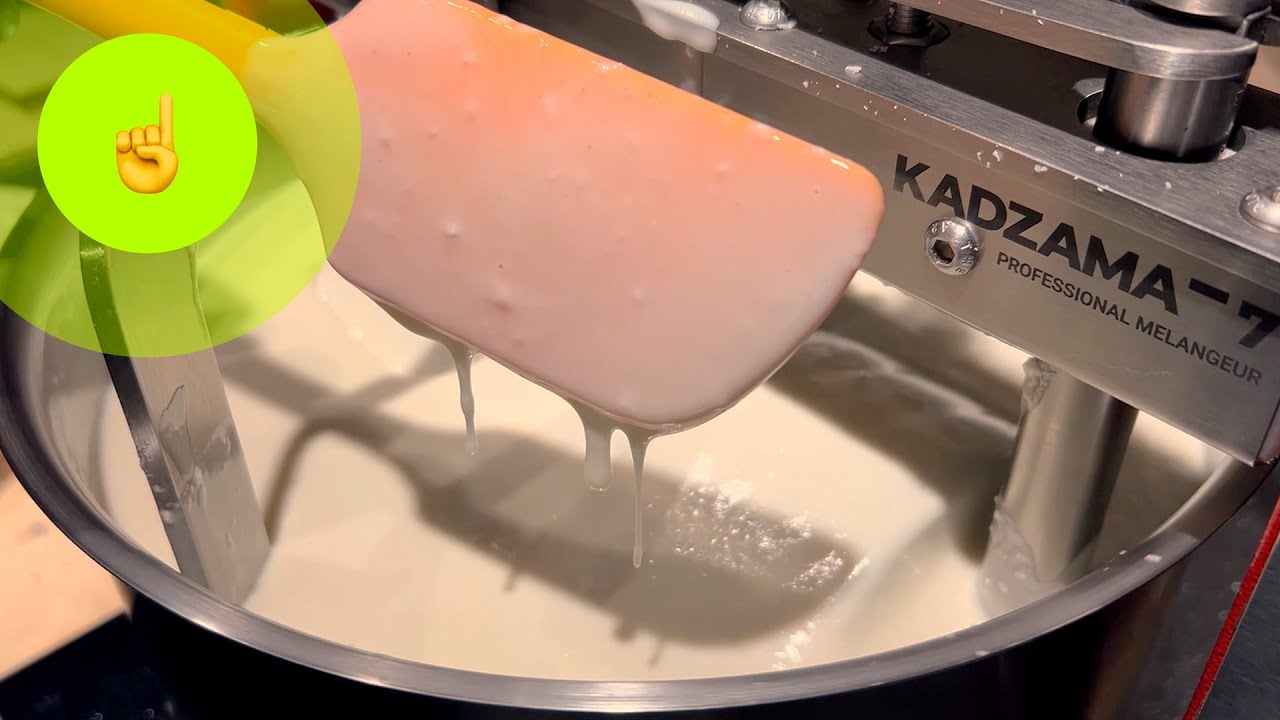

Melangeur 20 kg (retro-styled) is a professional mil, an universal machine for making chocolate, nut spreads, hummus, 100% nut and seed paste, pate, vegan milk and everything that requires grinding and mixing. The maximum load is 20 kg.

Melangeur combines 3 functions at once: PRE-GRINDING, FINE GRINDING and CONCHING. So you don’t need to have three different machines as at large factories — this is 3 in 1.

While designing the melangeurs of the retro-styled line, our designers were inspired by the legendary machines from the time of the first manufactories to give the equipment an authentic look with a hint of handicraft brutality.

Retro melangeurs are not equipped with a thermal sensor, reverse function and RCD, but they have the same stones, engine and capacity as our flagships with an authentic appearance that can bring the spirit of craftsmanship to any production or showroom, turning the melangeur’s work into a real performance.

One of the main competitive advantages of all KADZAMA melangeurs is the special patented groove of the grinding stones, which we call the «spiral groove». It differs from the classic «circular» not only by look — it also (most importantly) increases the intensity of grinding. This is especially great for whimsy ingredients such as coconut.

The spiral groove sets the grinding vector for the mass and makes it drag more intensively under the millstones. Such conditions make grinding work more evenly and more efficiently due to constant dynamics and a significant increase of contact spot between the mass and stones. So the size of the particles in the mass from a melangeur with a spiral groove is almost 2 times smaller compared to the standard circular one.

This solution is simpler than a bearing. The rotation of stones is facilitated, the chance of jamming during working is significantly reduced. Also runners with sleeves are easier to maintain: bushings are always in stock and it’s easy to replace them yourself following the instructions from the manager, rather than sending the melangeur to the service and waiting for a long time.

The spring mechanism allows the grinding stones to fit the bottom of the bowl tight and equable, ensuring perfect grinding without complex and expensive pneumatics. (the higher efficiency of pneumatic clamps in comparison with spring clamps hasn’t been proven in practice).

Allows easy loading and unloading the product and cleaning the leftovers.

Melangeur 20 kg (retro-styled) has a built-in circuit breaker that protects against short circuits.

All melangeur elements contacting the product are made of materials that meet the strict hygienic and toxicological standards.

To tilt the frame with the bowl you need to release and move the latch by loosening the clamp and then simply pull the handle.

Melangeur 20 kg (retro-styled) can be tilted and fixed in 3 different states:

- Working state (fully vertical);

- Cleaning state (at an angle of 60º);

- Drain state (maximum downward slope).

The advantage of the manual tilt is the ability to unload the bowl contents without problems even in the event of a power outage.

Melangeur 20 kg (retro-styled) is also equipped with four wheels, which will allow you to move it around the workshop to any place without much effort.

In addition to the melangeur, we have developed a vibrating sieve for cleaning chocolate from external elements accidentally got-in during grinding or insufficiently small unground pieces of beans. Simply place the vibrating sieve under the melangeur and then place the GN-container under the sieve to provide the cleanliness and safety of the product.

The vibrating sieve is not included with the melangeur. Sold separately.

All you need to do while working with a melangeur is to prepare the ingredients, put them into the bowl one by one and wait until the product, chocolate or paste is ready.

Melangeur 20 kg (retro-styled) is made from reliable and durable details that allow it to work safely without stopping 24/7. A table showing the required time for the melangeur to work without stopping to obtain a high ground quality product:

| Product | Required time |

| Chocolate | from 48 hours |

| Spreads | from 24 hours |

| 100% nut and seed paste | 8-24 hours |

| Plant-based milk | 8-12 hours |

| Dimensional size | 680 х 875 х 1050 mm |

| Weight | 130 kg |

| Loading capacity | 20 kg |

| Minimum loading capacity | 12 kg |

| Supply | 220-240 V~50 Hz |

| Power supply system | Single-phase |

| Power | 1,1 kW/h |

| Housing material | Steel |

| Bowl material | Food-grade stainless steel AISI 304, granite bottom |

| Rotation speed | 0 – 90 rpm |

| Package overall size | 1200 x 800 x 1550 mm |

| Package weight | 150 kg |

| Warranty period | 2 year |

-

If the chocolate in the melangeur is too thick, then causes may relate to:

Insufficient grinding time.

It will take about a day for the chocolate to pass into the liquid phase and become fluid.

Solution: Be patient and wait.

-

Loading of ingredients into the melanger is too fast.

Solution: Load the ingredients in small portions, starting with the fattest. To speed up the grinding process and the transition of the mass into the liquid phase, you need to increase the pressure of the millstones and, if necessary, heat the mass with a heat gun

-

Mass temperature during grinding is too high.

The chocolate has overheated and thickened.

Solution: Control the temperature, reduce it if it exceeds the allowable one. The allowable temperature mainly depends on the composition. Each nut or type of ingredient has its own characteristics, so the optimal temperature for grinding is usually 45–50ºC. Anything containing milk should not be heated above 60ºC for a long time.

-

Mass temperature during grinding is too low.

Solution: Heat up the mass with a heat gun.

-

Problem with the recipe.

If the substance's balance in the recipe is shifted to dry ingredients, such as sugar, skimmed milk powder, then the mass will be too thick.

Solution: Adjust the recipe by increasing fatty ingredients, their optimal content is from 35 to 40%.

-

If all of the above causes are excluded, but the mass still seems too thick, add lecithin at the end of the grinding (5–10 minutes before the melangeur stops). It improves the rheology (fluidity) of the mass and makes it more convenient in the further production of chocolate products.

-

Jamming of stones during the work may relate to the following:

Loading of ingredients into the melanger is too fast.

Solution: Load the ingredients in small portions, pausing, thereby allowing the already loaded ingredients to grind a little.

-

Loading fraction is too big (for small melangeur models).

Solution: Large ingredients such as almonds, hazelnuts, peanuts and others first need to be crushed to a finer fraction (the size of a bread crumb), and cocoa products (cocoa butter and cocoa liquor) need to be melted to a liquid state before being loaded into the melanger.

-

Temperature is too low, so ingredients, such as cocoa butter, harden.

Solution: Use a heat gun while loading the ingredients to heat up the mass (especially important for a cold room). It’s also important not to forget to adjust the pressure of the stones.

-

Caramelization of milk powder, sugar or other ingredients on sliding sleeves.

Solution: You need to monitor the temperature during grinding, so the axles are covered with the mass of the product and not overheat. Do not squeeze the clamps and slow down the speed if the mass is difficult for grinding.

-

A more serious reason for millstones to stop is sleeves wear.

Solution: To prevent premature wear, you need to follow the rule: load the melangeur with a mass to the level of the axles, so the sleeves are immersed in the mass — that serves as a lubricant and doesn’t allow dry working. If the sleeves remain dry during operation, then their wear occurs many times faster. Also solid particles of loaded ingredients, such as sugar, often get inside, caramelizes, hardens, makes it difficult to rotate the millstones and, as a result, leads to breakage. We recommend changing the sleeves once a year if your melangeur works full-time.

-

Usually unground particles remain in some masses even after prolonged grinding of 1–2 days (for example, sesame seeds). These unground particles can be seen floating on the surface of the mass. The causes may relate to an incorrectly selected millstones rotation speed. If the rotation is too fast, the particles do not have enough time to be dragged under the stones and remain unground.

Solution: You need to gradually reduce the speed of the millstones until the mass from the surface begins to drag down. Check this video.

-

The stones and the bottom may have various irregularities and may not fit perfectly. During the work these irregularities are erased and the contact becomes tighter. So the new melangeur may not be as effective as the used one. The bedding time depends on how many irregularities there were initially. Sometimes parts can fit perfectly right from the box.

-

Any new melangeur requires bedding of stone parts. During it more stone dust gets into the chocolate. So if you load a white chocolate recipe into a new melangeur that hasn’t yet been lapped, then most likely the mass will have a grayish tint. While making dark/milk chocolate or any other dark masses, the bedding process goes unnoticed. This does not affect the taste of the finished product.

Solution: If the melangeur produces a gray mass, then it must be stopped, disassembled and washed (axles with bushings). Then reassemble everything. Contact your KADZAMA manager for a melangeur’s self-service video instruction..

-

Melangeur is not just about grinding, there are 3 processes: pre-grinding, fine grinding and conching. We’ve been able to reduce the grinding time with our patented spiral grooved stones.

More about spiral groove here.

-

Milk particles stick together as a result of prolonged mass heating above 60°C.

Solution: Monitor the temperature of the mass during grinding and do not allow heating above 60ºC. The mass heats up due to the friction force of the stones, you can reduce the temperature by reducing the rotation speed of the millstones. Melangeurs of our classic line (35/65/85 kg) have a built-in smart thermal sensor — you set the maximum allowable temperature of the mass, and the melangeur monitors the speed of work itself to not overheat the contents.

The minimum load of melangeur can be found in the table:

| Melangeur 7 kg | 4,5 kg |

| Melangeur 35 kg | 20 kg |

| Melangeur 65 kg | 40 kg |

| Melangeur 85 kg | 50 kg |

| Melangeur 7 kg lite | 4,5 kg |

| Melangeur 20 kg (retro-styled) | 12 kg |

| Melangeur 40 kg (retro-styled) | 25 kg |

| Melangeur 65 kg (retro-styled) | 40 kg |

| Melangeur 90 kg (retro-styled) | 55 kg |

You must load the melangeur by the level of the axles, so the sleeves are completely covered with mass. This is necessary in order to avoid jamming of stones and to reduce sleeve wear (check picture).

Sending...

Sending...